BioMechanical Engineering Lab

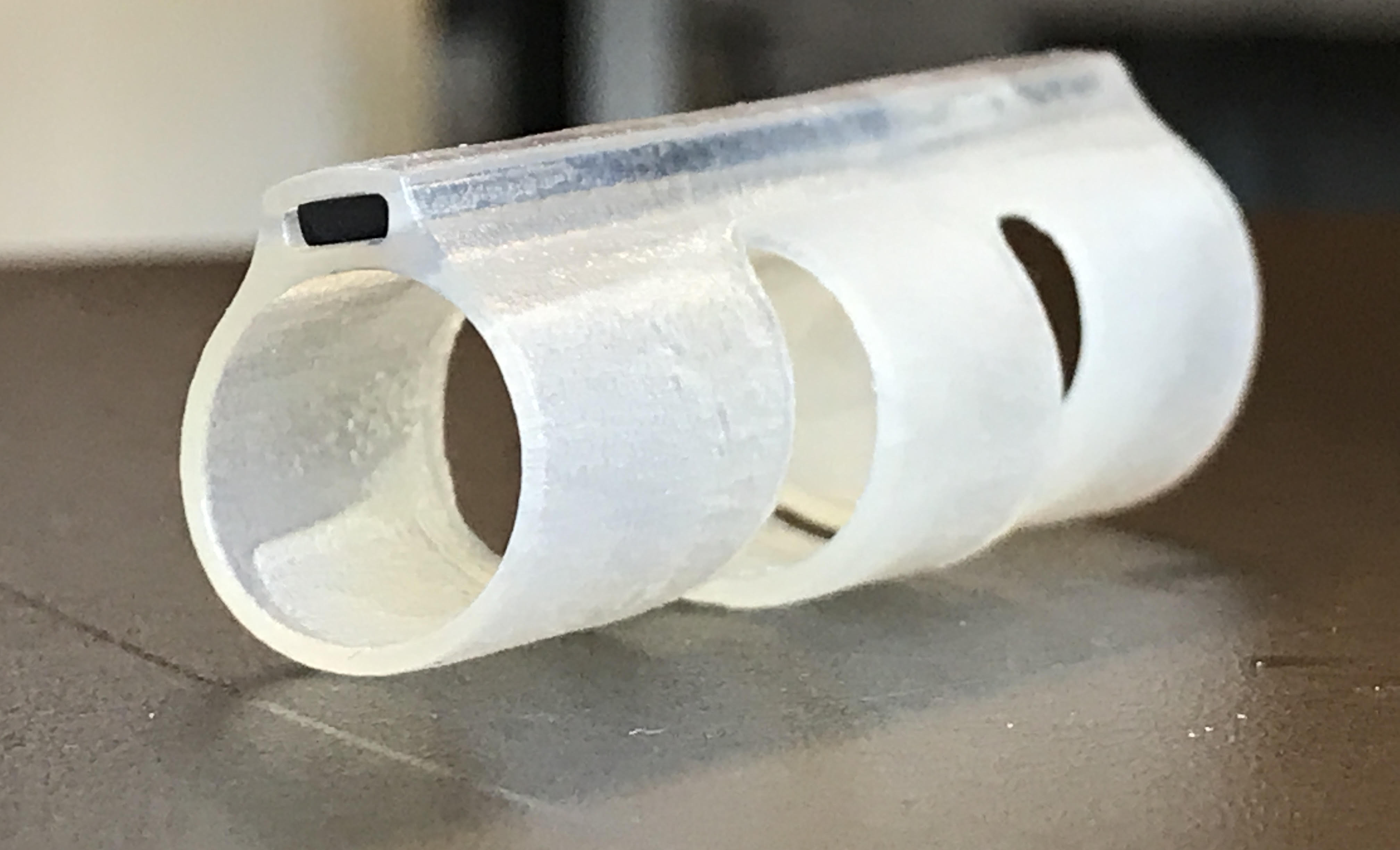

The BioMechanical (Biomedical) Engineering Research Lab (BME Lab) is established to design and manufacturing orthoses and devices for people with all sorts of deformity. The patented biomedical devices are composite devices comprised of polymer, and carbon fiber (or metal).

We are currently looking for licensees/manufacturers who can help us bring the composite biomedical supports to the market. Please email the inventor.

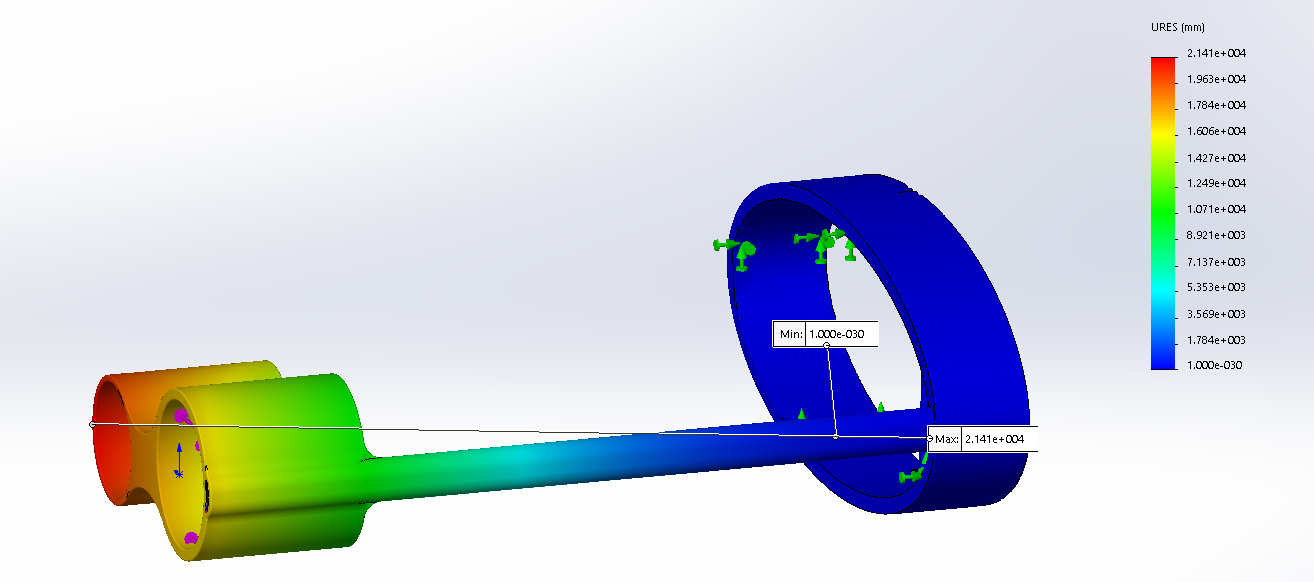

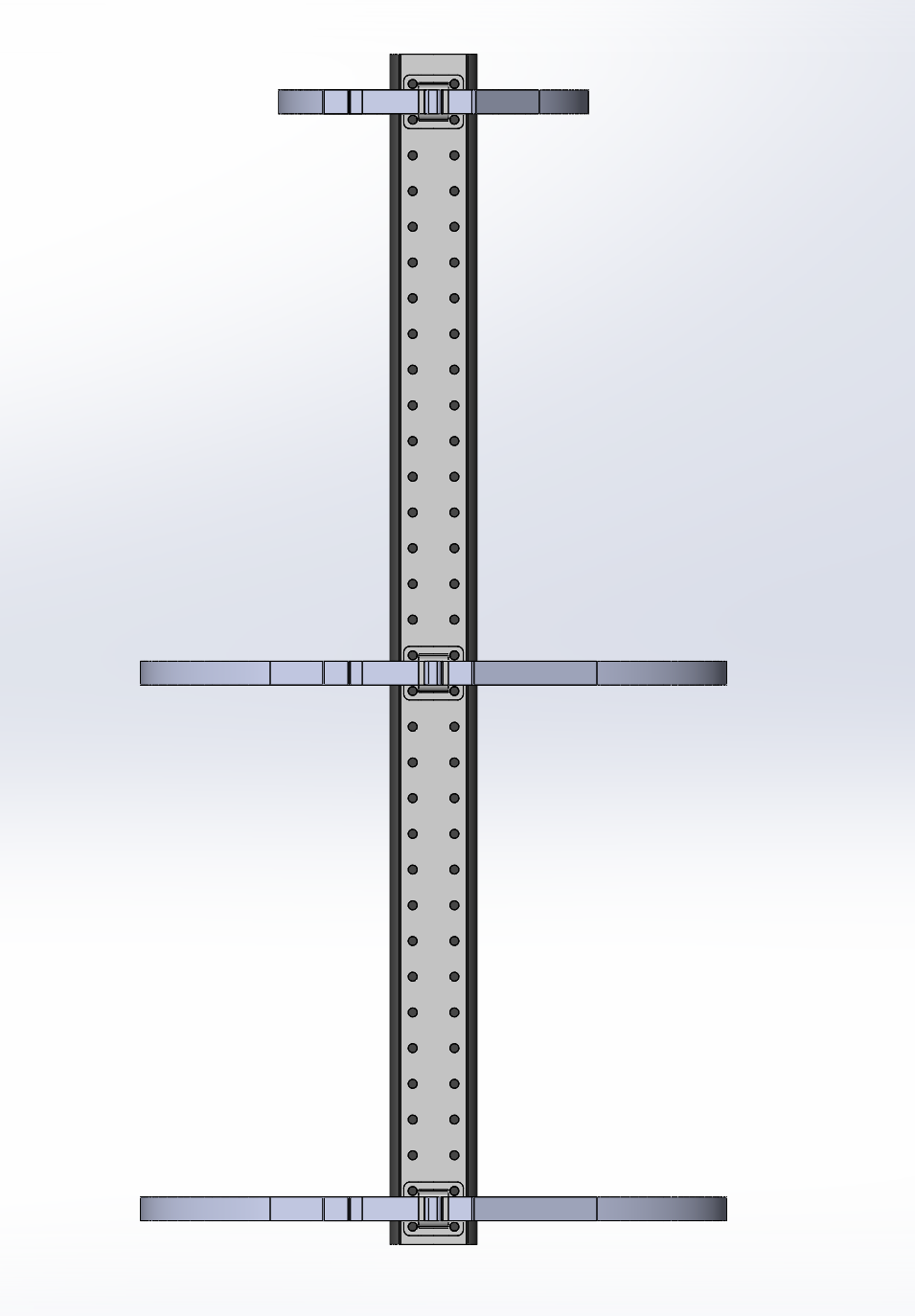

The BME lab is designed to integrate mechanical testing with experimental techniques from fundamental anatomy to clinical studies (including direct patient studies). This BME laboratory includes facilities for 3D printing, mechanical testing, deformity measurements. The results are then compared with the results obtained by advanced computer simulation (using Solidworks, MATLAB, etc.).

Projects People Equipment Patents and Papers News/ Media Appearance=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=

=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=

Simin Nasseri (Ph.D., P.E.), Currently a full professor at Kennesaw State University

Simin Nasseri (Ph.D., P.E.), Currently a full professor at Kennesaw State University

Dr. Simin Nasseri currently works at the department of mechanical Engineering, Kennesaw State University (USA) as a full professor. She is recognized as the University's Distinguished Professor. Simin does research in Mechanical Engineering. At the moment, her recent projects are related to manufacturing engineering and biomechanical engineering. Formerly, she conducted research projects related to Rheology and viscoelasticity, Polymer processing, Biomechanical engineering (artificial organs and soft tissue rheology), Computational Mechanics and CFD (Parallel Computing via PVM, Finite Element Method, Boundary Element Method, Completed Double Layer Boundary Element Method), Robotics, and Micromachinery. See more here.

Dr. M. Jonaidi obtained his Ph.D. from the University of Sydney and is currently working at Civil and Environmental Engineering Department, KSU. Over 38 years of research and industry experience, he has been involved in the analysis and design of complex structural projects, including FEA of high-rise buildings and steel structures, floor vibration analysis for concrete slabs and pedestrian bridges, serviceability vibration analysis of high-rise buildings, earthquake engineering, post-tensioned concrete structures, nonlinear and buckling analysis of thin-walled cylinders, analysis of long-span spatial steel structures, analysis of glazing facades, below-grade shoring walls, retrofit of concrete structures using Fiber Reinforced Polymers (FRP), and the strengthening of structures to resist progressive collapse. See more here.

Kyle Vitale Castellano (Lead Student), Ph.D.,

Vitale "Kyle" Castellano obtained his Ph.D. in Mechanical Engineering from the Auburn University in 2022. He recieved the Auburn University Presidential Research Fellowship. He completed his undergraduate degree in Mechanical Engineering Technology (MET) at Kennesaw State University, formerly Southern Polytechnic State University. He graduated with his Bachelors of Science Summa Cum Laude and was the 2017 MET Student of the Year. Kyle was Dr. Nasseri's student in five classes and a Reserach Assistant in 2017, on projects related to Manufacturing and Biomedical engineering. Kyle has extensive knowledge in machine design, 3D printing, and computer aided engineering. He has been using computer aided design software for over ten years and holds the Certified SolidWorks Professional License. He is an expert when it comes to implementing the engineering design process to solve complex problems in a timely manner.

George Williams (Lead student), Currently a Mechanical Engineer at Compass Technology Group

George Williams obtained his B.Sc. in Mechanical Engineering from KSU in 2021. He worked with Dr. Nasseri's BME team from 2019 to 2021 to develop noninvasive orthoses for treating musculoskeletal pathologies; and with Dr. Jonaidi in CEE department, to develop novel relief details for column-slab connections in reinforced concrete. As a former president of Kennesaw Motorsports, he designed and manufactured performance IC/EV powertrain components for Formula SAE vehicles. He currently works as a mechanical engineer at Compass Technology Group, LLC, focusing on electromechanical design/drafting, conventional/ computational analysis in structural, fluid/thermal/EM systems (FEA, CFD, CEM), manual and CNC machining, computer-aided manufacturing (CAM), and industrial control systems integration. See more here.

Timothy Plowman, Currently working as Continuous Improvement Engineer at StimLabs

Tim Plowman graduated from Auburn University with a B.Sc. Degree in Mechanical Engineering and a Minor in Industrial/Graphic Design. In 2020, Tim obtained his Master's degree in Mechanical Engineering from KSU. He joined Dr. Nasseri’s research team in 2021, where he worked as a Research Assistant in the BME research group, performing extensive computer simulations using SolidWorks for foot, spine and shoulder supports. Tim currently works as a Quality Engineer for Stimlabs, a local regenerative medicine company, where he uses Lean Six Sigma methods to analyze and improve equipment processes and write and execute equipment validations.

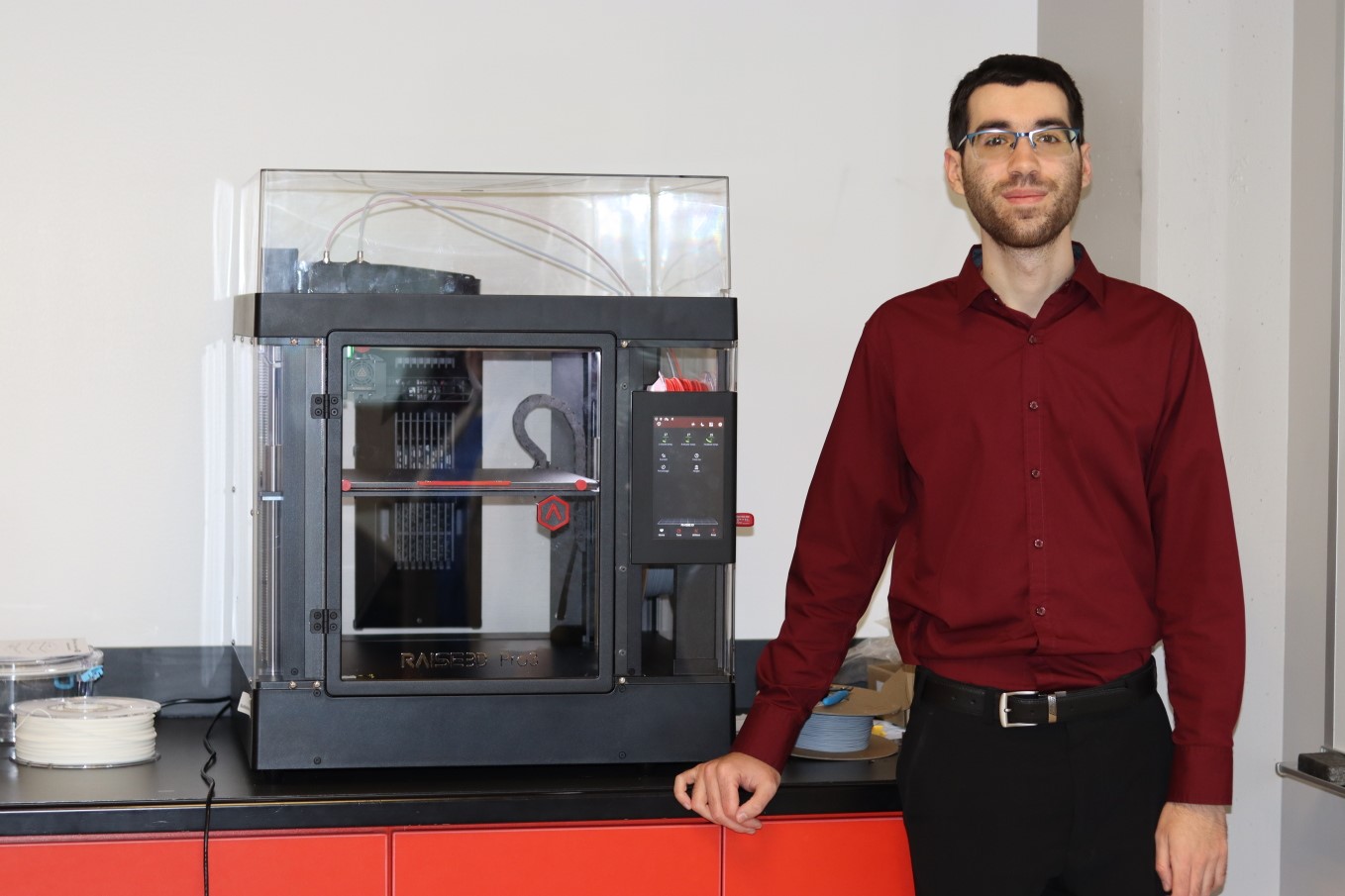

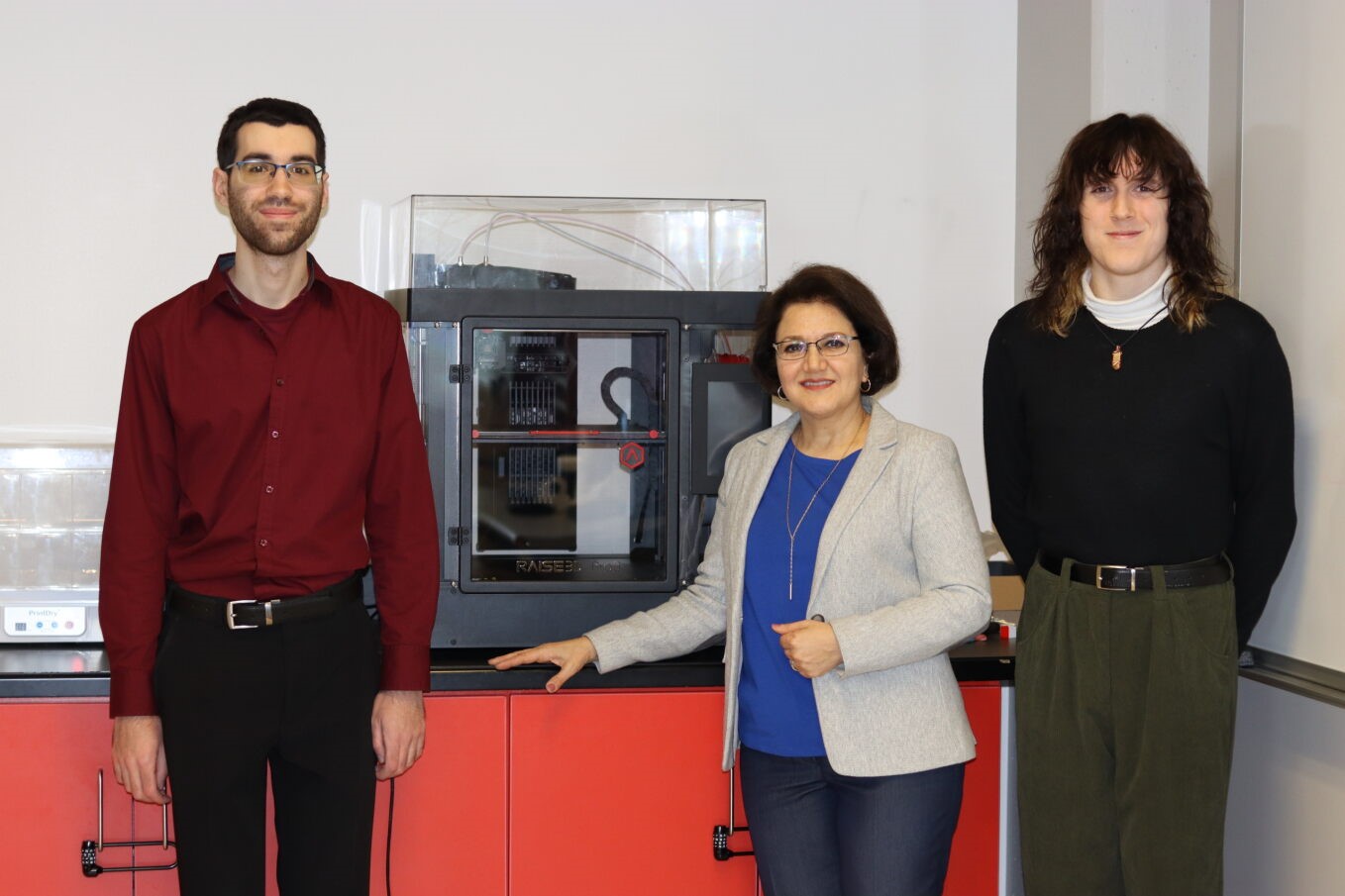

Salim Kortobi (lead student) earned his M.S. in Mechanical Engineering from Kennesaw State University (KSU), where he also graduated Summa Cum Laude with a B.S. in Mechanical Engineering and minors in Engineering Design Graphics and Manufacturing Engineering Technology. He is currently an instructor of Mechanical Engineering at KSU. Salim is a Certified SolidWorks Expert (CSWE) in Mechanical Design, a credential held by a small percentage of users worldwide. His expertise includes modeling, simulation, and additive manufacturing. During his time at KSU, he worked on various research projects from 2022, including developing finger, foot, and spine orthoses and FVD project under Dr. Nasseri (as GRA, through the independent research assistantship and through the "Graduate Research" class), and characterizing structural components with internal composite structures under Dr. Jonaidi. Salim has extensive expertise in Additive Manufacturing (3D printing), which he utilized to help establish the BioMechanical Engineering Lab (BME Lab) at KSU. He also trains students and team members in advanced techniques and equipment usage within the lab. Additionally, he has extensive experience in Finite Element Analysis (FEA) and SolidWorks Simulation, which he uses to conduct detailed simulations for ongoing research and to train team members. His research contributions span biomedical supports and structural damping systems, with a focus on applying advanced design and Finite Element Method-based tools to real-world engineering problems.graduated Summa Cum Laude from Kennesaw State University with a B.S. in Mechanical Engineering with minors in Engineering Design Graphics and Manufacturing Engineering Technology, and is currently pursuing his M.S. in Mechanical Engineering at KSU. He has extensive experience in SolidWorks and is a Certified SolidWorks Expert (CSWE) in Mechanical Design. As a SolidWorks training consultant, he empowers professionals to optimize their workflows and achieve outstanding project outcomes by effectively leveraging the software's tools and techniques. Salim also has extensive expertise in Additive Manufacturing (3D printing), which he utilized to help establish the BioMechanical Engineering Lab (BME Lab) at KSU, where he also trains students and team members in advanced techniques and equipment usage. As a research assistant for Dr. Nasseri and Dr. Jonaidi, Salim has contributed to various projects, including the development of finger, foot, and spine supports, along with the fluid viscous dampers (FVD) project. He also has extensive experience in Finite Element Analysis (FEA) and SolidWorks Simulation, which he has utilized to run detailed simulations that support ongoing research efforts, and to provide training for team members in these advanced techniques..

Logan Willis graduated from Kennesaw State University in 2020 with a Bachelor’s degree in Mechanical Engineering. During his time at KSU, he joined Dr. Nasseri’s team as a research assistant to help create custom orthotic devices for foot and spine support. Shortly after graduating, Logan obtained a full-time position as an engineer and worked on predictive maintenance systems for water transportation systems. See his current status here.

Connie Pruitt began at Kennesaw State University in 2020, to pursue a Bachelor of Science in Mechanical Engineering, with a minor in Environmental Engineering. In early 2023, she joined the BME Lab team. Connie is experienced with 3D printing which is mostly self taught and learning advanced FEA methods for composite materials. As part of the KSU Innovation Launch Pad, she attended the BIOMEDevice Conference in Boston in Sep 2023, where she met and networked with engineers and executives from various medical companies. Overall, she intends to make real progress in the various projects encompassed by this lab.

Marie-Paule Aguegue joined KSU in 2021 with a major in Mechanical Engineering, and a minor in Mathematics.

She took Machine Dynamics and Vibrations with Dr.Nasseri, and became interested in

the research she was involved in. She is interested in the work that can be accomplished

using 3D printing, especially as it pertains to the field of Biomedical Engineering.

Marie-Paule Aguegue joined KSU in 2021 with a major in Mechanical Engineering, and a minor in Mathematics.

She took Machine Dynamics and Vibrations with Dr.Nasseri, and became interested in

the research she was involved in. She is interested in the work that can be accomplished

using 3D printing, especially as it pertains to the field of Biomedical Engineering.

Katie Cho is currently pursuing a Bachelor of Science in Mechanical Engineering, with a minor

in Biomedical Engineering. She is interested in the clinical applications of mechanical

principles and biomedical research.

Katie Cho is currently pursuing a Bachelor of Science in Mechanical Engineering, with a minor

in Biomedical Engineering. She is interested in the clinical applications of mechanical

principles and biomedical research.

Solomon Olamidipupo Ibiloye began studying at Kennesaw State University in fall 2023, aiming for a bachelor's

degree in Mechanical Engineering and a minor in Aerospace Engineering. He is also

part of a team at the university that is building a small, self-flying drone, where

he is gaining hands-on experience. Solomon has learned to use Solidworks design software

and some laser cutting tools, and he is currently learning programming with MATLAB

and Python.

Solomon Olamidipupo Ibiloye began studying at Kennesaw State University in fall 2023, aiming for a bachelor's

degree in Mechanical Engineering and a minor in Aerospace Engineering. He is also

part of a team at the university that is building a small, self-flying drone, where

he is gaining hands-on experience. Solomon has learned to use Solidworks design software

and some laser cutting tools, and he is currently learning programming with MATLAB

and Python.

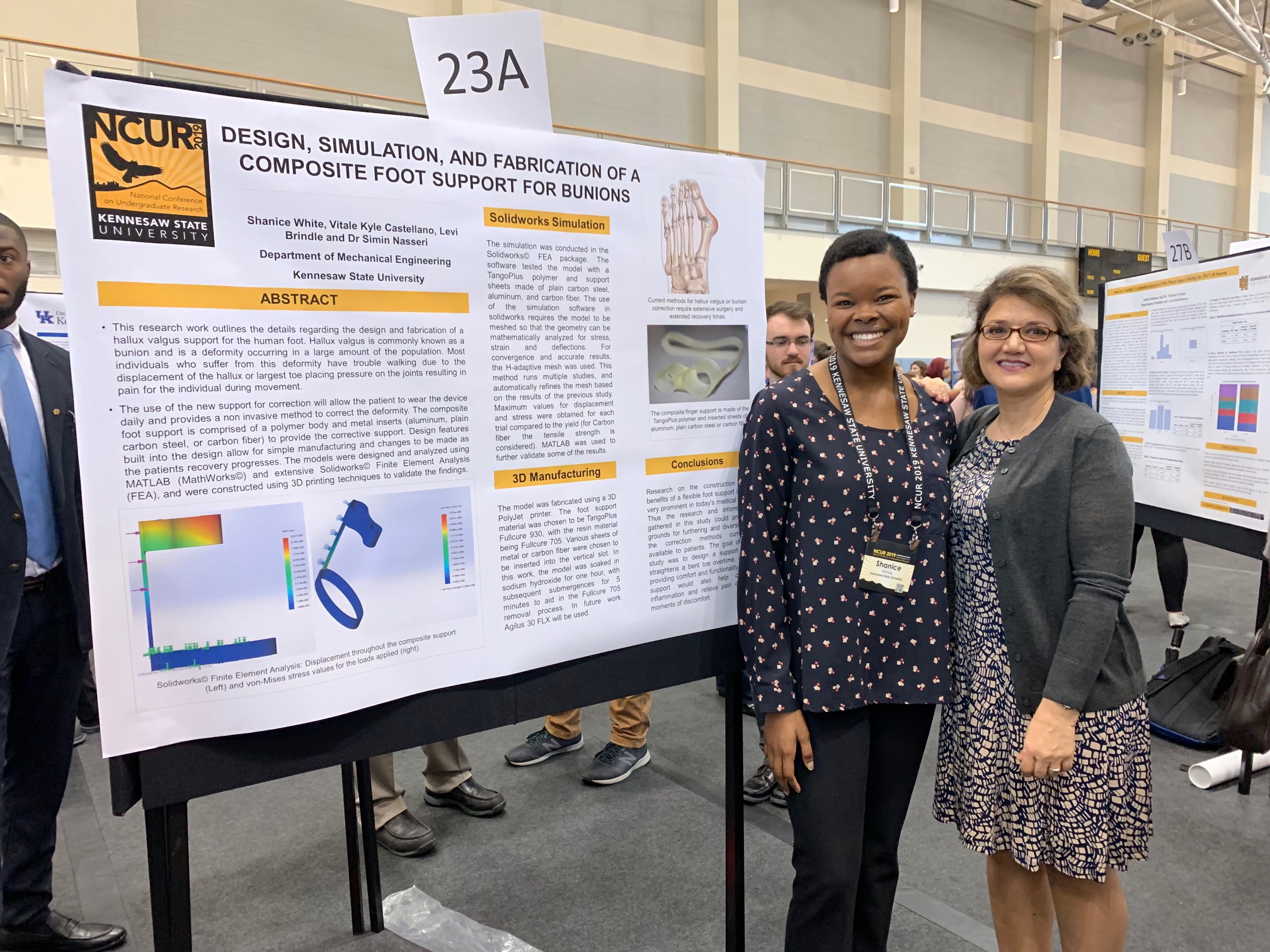

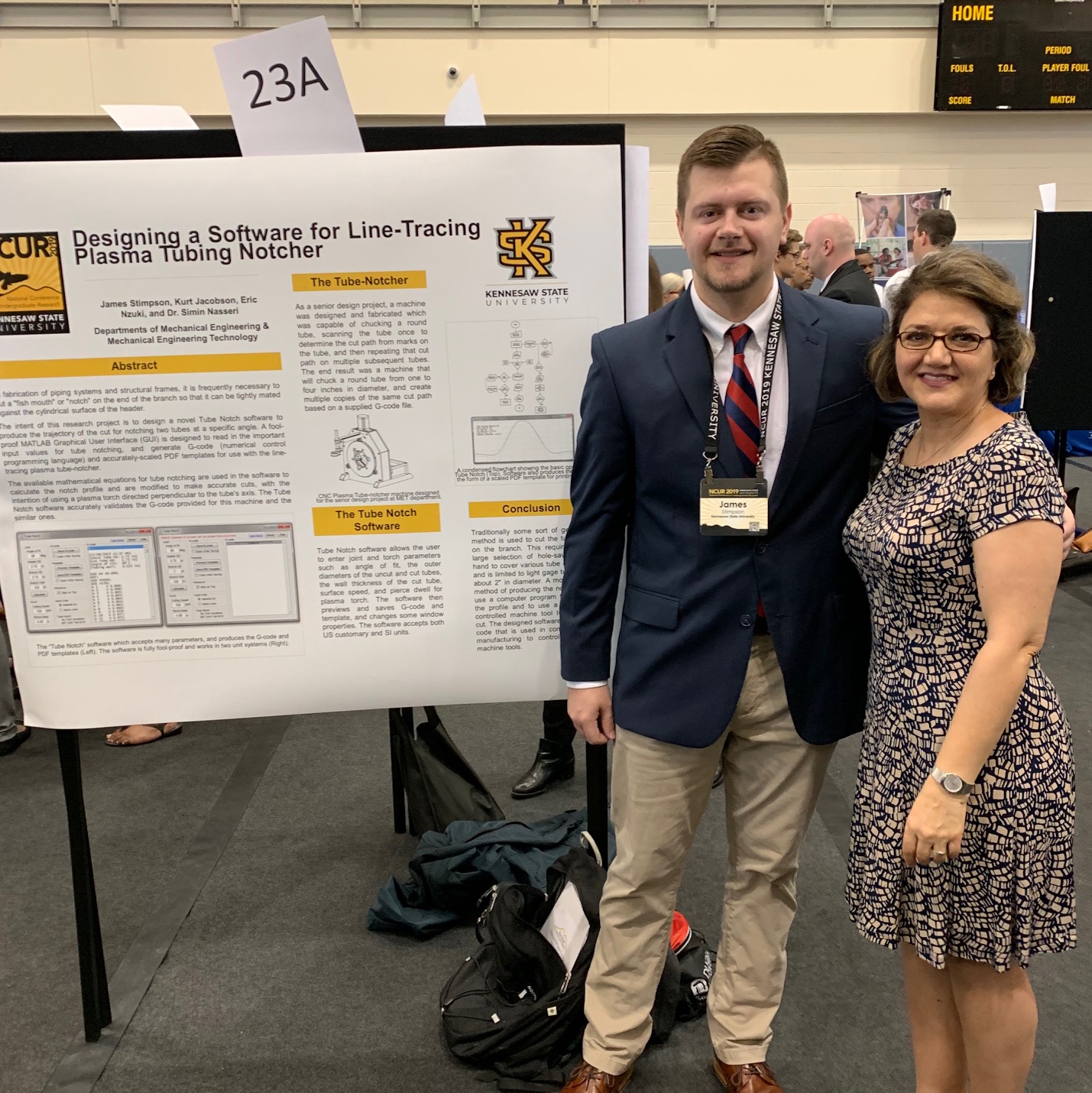

Former students in this research group: Jesse Pressley, Bailee Garcia, Mushfequr Kotwal, Daniel Stimpson (Manufacturing), Lei Brindle, Shanice White, Tammy Ong, Barrett Tallant and Anthony DeDiego Jr.

Click on each image to see a larger size.

=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=

Patents:

- Full or Non-provisional patent: Systems and Methods for Appendage Support, 2021-2024 (EFS ID TBA, and Application number TBA). Filed on 01/14/2021. For modified bunions supports, bunions insoles, bunions band-aids and spine supports. Application Number: 17/148891, Publication Number: US2021212850A1 (07/15/2021). Ranking: Top Assignees for A61F.

- Patent: Systems and Methods for Appendage Support, 2020 (EFS ID 38293251, and Application number 16742520). For finger and foot supports.

- Designing the spine supports for patients with deformity, 2020 (EFS ID 38293386, and Application number 62960984).

- Designing finger and foot supports for patients with deformity, 2019 (EFS ID 34846513 and Application number 62792099). Patent Application Publication: US20200222222A1.

Peer-Reviewed Journal/Conference Papers and Posters/Presentations:

- Nasseri S., Jonaidi, M., Kortobi, S., Williams G., and Willis L. (2023) Design, Finite Element Analysis and Fabrication of Composite Orthoses for Bunions; A Comprehensive Study. Int. Journal of Product Sound Quality, Special Issue: Structural, Vibration Analysis, Design, Control and Applications. 1(1)- 59-77. https://doi.org/10.1504/IJPSQ.2023.133665

- Nasseri S., Jonaidi, M., Kortobi, S., Williams, G. and Plowman, T. (2023) Design and Evaluation of a New Composite Spine Support. Int. Journal of Product Sound Quality, Special Issue: Structural, Vibration Analysis, Design, Control and Applications. 1(1)- 78-90. https://doi.org/10.1504/IJPSQ.2023.133667

- Pruitt, C., Nasseri, S., Jonaidi, M., BIOMEDevice Conference in Boston, "Special Composite Orthoses- Sponsors' Delegation," MEDevice Boston. (September 25, 2023).

- Nasseri, S., Jonaidi, M., Williams, G., Garcia, B., Georgia Bio-Innovation Summit Conference, 2021, "On Patented Finger, Foot and Spine Supports for Patients with Deformity," Virtual. (October 2021).

- Nasseri, S., White, S., Design, Simulation and Fabrication of a composite Food support for Bunions, Presented at National Conference on Undergraduate Research (NCUR), Kennesaw, Ga, April 2019.

- Nasseri, S., Williams, G., Reed, S. (2019). Design and Fabrication of a New Foot Support- Phase 2-Presentation. GURC, Nov 2019.

- Nasseri, S., Marak, A., Nzuki, E. (2019). Designing a Software for Line-Tracing Plasma Tubing Notcher- Phase 2. GURC, Nov 2019.

- Nasseri, S., White, S. (2019). Design and Fabrication of a New Foot Support, Phase I- Poster Presentation. NCUR, 2018-2019.

- Nasseri, S., Castellano, V. K., Ong, T., DeDiego, A., Nasrin, N., Design, simulation and fabrication of a new finger support. International Journal of Current Engineering and Technology, Vol 8, No 4, July/Aug 2018. https://doi.org/10.14741/ijcet/v.8.4.9

- Nasseri, S., Castellano, V. K., Kotwal, M., On fabrication and mechanical testing of a new finger support. International Journal of Current Engineering and Technology, Vol 8, No 4, July/Aug 2018. https://doi.org/10.14741/ijcet/v.8.4.8

- Nasseri, S., Castellano, V. K., Kotwal, M., "Research methods in designing various finger supports for patients with deformity," Presentation in the 6th Annual Southeast Preeminent Regional Research & Creative Endeavors Conference, Georgia College & State University, Oct 27-28, 2017.

=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=

- Dell Precision 5570 i9 processor for Parallel Virtual Machine Projects (PVM) ( total of 3)

- 3D Printer (Raise 3D Pro3)

- Build Plate with Protector Pro 3 / Pro 3 Plus

- Interchangeable Hot End Assembly Pro 3 / Pro 3 Plus (total of 4)

- V3 Hardened Nozzle - 0.4mm (total of 5)

- Infinite Material Solutions AquaSys 120 1.75mm

- Filament Guide Tube - Pro 3 / Pro 3 Plus

- PrintDry Filament Dryer PRO

- PrintDry Vacuum Container

- Overture TPU Filament

- CC3D Silk PLA

- Neoprene Rubber Sheet (1/32")

- Einstar 3D Scanner

- BEAMNOVA 6" Metal Sheet Cutter

- Pipe/Tube Cutter

- Digital Protractor, Digital Level, Digital Hand Dynamometer

- Digital Newton Meter, Digital Goniometer

- Flexible Ruler, Strain Gauges, Angle Vise with Swivel Base

- HATCHBOX TPU, Carbon Fiber Sheet 1mm, 3M Micropore Paper Tape

- Digital Caliper 8", Digital Dial Gage, Weight Set, Socket Wrench Set, Special Pliers

=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=_._=-=

Media Appearance:

- SCREECH News, on Full Patent and Journal papers

- KSU news: Engineered Recovery (Designing finger and foot supports to correct deformities)

- Medical Design Briefs

- Cobb Chamber

- Synectic

- KSU News on George Williams